Hot cells and shielded systems

Cegelec CEM has been designing, building, installing and commissioning hot cells and complex shielded systems for 35 years.

Shielded systems, hot cells and the associated equipment are central to Cegelec CEM’s turnkey activities for all research and scientific facilities, for project owners CEA and EDF, and for the sorting, measurement and reconditioning of nuclear waste.

Shielded systems, hot cells and the associated equipment are central to Cegelec CEM’s turnkey activities for all research and scientific facilities, for project owners CEA and EDF, and for the sorting, measurement and reconditioning of nuclear waste.

Thanks to its own technological resources and innovations, Cegelec CEM’s offer ranges from…

- Our specialised engineering services – the design of shielded lines takes into account all types of constraint: leak tightness, ventilation, radiological protection, mechanical and seismic resistance, operation, protection against magnetic waves, confinement, fire protection, operating safety, ergonomics and human and organisational factors, among others

- Fabrication on site or pre-fabrication in the factory and integration into buildings

- Equipment: shielded doors, containment enclosures, airlocks, grippers and other systems for handling, sorting, cutting, conditioning and docking in cells

- Integration of off-the-shelf equipment (remote-controlled arms, shielded windows, transport casks, measuring instruments, etc.) and customisation for nuclear environments

- Site installation, commissioning and tests

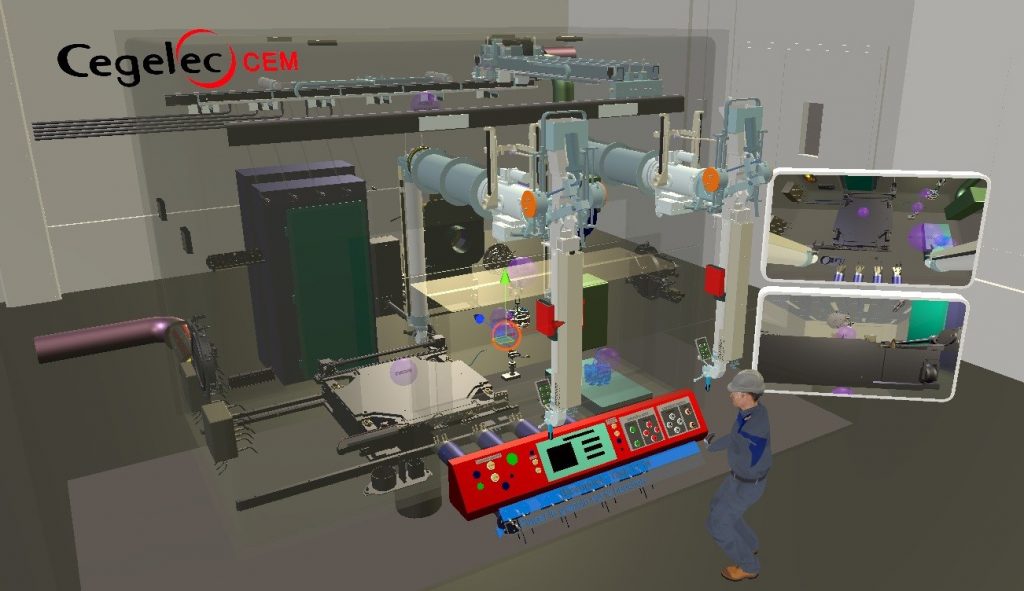

- … all the way up to operator training, including the use of virtual reality.

Remote handling

Cegelec CEM’s remote handling solutions for nuclear environments are collaborative thanks to:

- Our customer-centric approach, which favours co-construction of the project

- Our collaborative virtual reality platform, which – starting with the digital twin – makes it possible to simulate and practise remote handling operations, such as the transfer of drums to storage racks in hot cells, or waste measurement and reconditioning